+91 9953 65 9594

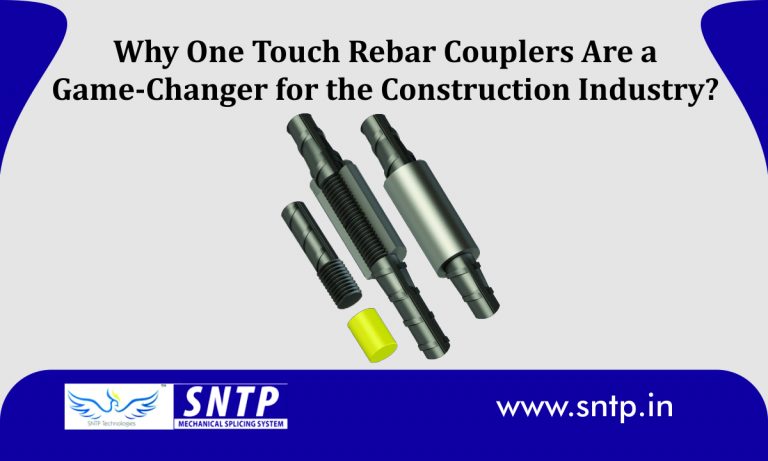

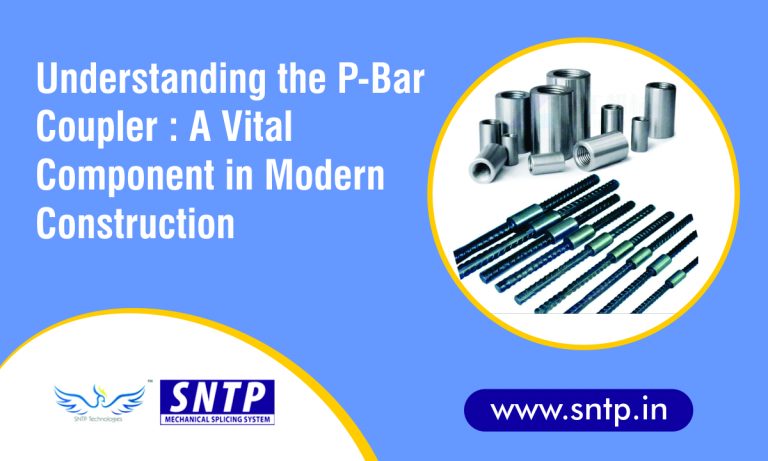

Understanding the P-Bar Coupler: A Vital Component in Modern Construction

Construction technology has evolved significantly over the years, with innovations that prioritize safety, efficiency, and durability. One such innovation is the P-Bar Coupler, a critical component widely used in the construction of buildings, bridges, and other infrastructure projects. This blog explores the importance of the P-Bar Coupler, its applications, and why it has become an indispensable element in modern construction.

What is a P-Bar Coupler?

A P-Bar Coupler is a mechanical splice used to connect two reinforcing bars (rebars) in construction. Unlike traditional methods such as lap splicing or welding, the P-Bar Coupler provides a more efficient and reliable connection between rebars. It ensures structural integrity, reduces material wastage, and simplifies the construction process.

These couplers are made from high-quality steel and are designed to withstand high loads and stresses, making them ideal for applications in demanding environments.

Advantages of Using P-Bar Couplers

1. Enhanced Structural Strength

P-Bar Couplers create a direct mechanical connection between rebars, ensuring consistent strength across the joint. This eliminates the weak points often associated with lap splices and welding.

2. Material and Cost Efficiency

By minimizing the need for overlapping rebars, P-Bar Couplers reduce the overall steel usage in a project. This not only cuts costs but also contributes to sustainable construction practices.

3. Easy Installation

These couplers are easy to install and require minimal specialized training or equipment. This simplicity speeds up the construction process and reduces labor costs.

4. Versatility

P-Bar Couplers can be used in a wide range of applications, from high-rise buildings to bridges, ensuring adaptability to various construction needs.

5. Improved Seismic Performance

In regions prone to earthquakes, P-Bar Couplers enhance the seismic resilience of structures. Their robust connections allow buildings and infrastructure to withstand dynamic forces more effectively.

Applications of P-Bar Couplers

P-Bar Couplers are versatile and find applications in numerous construction scenarios:

- High-Rise Buildings: Ensuring structural integrity in vertical columns and beams.

- Bridges: Providing reliable connections in the reinforcement of piers and decks.

- Industrial Structures: Used in factories, warehouses, and heavy-duty facilities.

- Tunnels and Subways: Reinforcing structures in underground construction.

- Retrofitting Projects: Strengthening existing structures without extensive modifications.

Types of P-Bar Couplers

P-Bar Couplers are available in various types to suit different construction needs:

- Standard Couplers: Ideal for general-purpose applications.

- Position Couplers: Used when neither rebar can be rotated during installation.

- Transitional Couplers: Designed to connect rebars of different diameters.

- Taper-Thread Couplers: Provide a strong, threaded connection for maximum load capacity.

How P-Bar Couplers Revolutionize Construction

The introduction of P-Bar Couplers has transformed the construction industry by offering a solution to challenges such as:

- Space Constraints: Their compact design allows for efficient use of space, especially in congested areas.

- Durability Issues: High-quality materials and precise engineering ensure long-lasting performance.

- Safety Concerns: Reliable connections reduce the risk of structural failures, enhancing overall safety.

Sustainability in Construction

With growing emphasis on eco-friendly practices, P-Bar Couplers contribute to sustainable construction. By reducing steel wastage and enabling resource-efficient designs, they align with global efforts to minimize the environmental impact of construction activities.

Choosing the Right P-Bar Coupler

When selecting a P-Bar Coupler, consider the following factors:

- Load Requirements: Ensure the coupler can handle the intended loads and stresses.

- Material Quality: Opt for couplers made from high-grade steel for durability and performance.

- Compliance with Standards: Verify that the coupler meets relevant industry standards and certifications.

Conclusion

The P-Bar Coupler has emerged as a game-changer in modern construction, providing superior strength, efficiency, and reliability. Its versatility and sustainability make it an essential component in projects ranging from residential buildings to large-scale infrastructure.

SNTP’s P-Bar Couplers are a game-changer in the construction industry, offering unmatched strength, efficiency, and reliability. By simplifying the splicing process and ensuring durable connections, they help projects achieve structural excellence while reducing costs and environmental impact.

Whether you’re constructing a skyscraper, a bridge, or an industrial facility, SNTP’s P-Bar Couplers are the ideal choice for your reinforcement needs. Partner with SNTP for quality you can trust and performance that lasts.

For more information about SNTP’s P-Bar Couplers, reach out today and take your construction projects to the next level!

© Copyright 2017.SNTP All Rights Reserved.

Design & Developed By Star Web Maker