+91 9953 65 9594

Weld Couplers: The Backbone of Structural Reinforcement

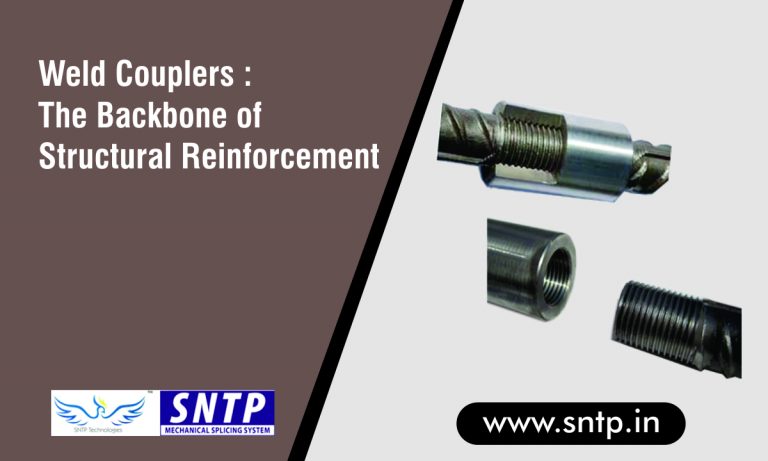

In the world of construction and engineering, weld couplers have emerged as a pivotal component in ensuring the strength, reliability, and durability of reinforced concrete structures. Designed to connect reinforcement bars (rebar) securely, weld couplers enhance the structural integrity of buildings, bridges, dams, and other critical infrastructure. This blog delves into the significance, applications, and benefits of weld couplers in modern construction.

Understanding Weld Couplers

Weld couplers are specialized mechanical connectors used to join two rebars end-to-end. They are typically made of high-strength steel, ensuring optimal performance under extreme loads and conditions. By eliminating the need for lapping rebars, weld couplers provide a more efficient, economical, and robust alternative to traditional reinforcement practices.

Key Features of Weld Couplers

- Strength and Durability

Weld couplers offer superior tensile and compressive strength, making them ideal for high-stress applications. They maintain the continuity of the reinforcement bars, ensuring uniform load distribution. - Precision Engineering

These couplers are manufactured with high precision to ensure seamless alignment and connection between rebars, minimizing potential weak points in the structure. - Corrosion Resistance

Weld couplers are often coated with anti-corrosive materials, ensuring long-lasting performance even in harsh environmental conditions. - Ease of Installation

Designed for quick and efficient installation, weld couplers reduce construction time, allowing projects to stay on schedule.

Applications of Weld Couplers

- High-Rise Buildings

Weld couplers are extensively used in skyscrapers to provide the necessary reinforcement for vertical columns and beams. They ensure stability and resilience against wind and seismic forces. - Bridges and Flyovers

In bridge construction, weld couplers play a critical role in connecting rebars for long spans, offering structural integrity to withstand heavy traffic and environmental stresses. - Industrial Structures

Weld couplers are indispensable in factories, warehouses, and power plants where reinforced concrete is required to endure dynamic loads and vibrations. - Marine Structures

For docks, jetties, and offshore platforms, weld couplers offer corrosion resistance and robustness, ensuring the longevity of these structures in saline environments. - Infrastructure Projects

From metro rail projects to dams and tunnels, weld couplers are widely used to streamline construction and enhance the structural performance of reinforced concrete elements.

Benefits of Using Weld Couplers

- Cost Efficiency

By eliminating the need for overlapping rebars, weld couplers reduce material wastage, saving both time and money in large-scale projects. - Space Optimization

Weld couplers allow for a compact and clean connection, minimizing congestion in reinforced concrete sections. This is particularly beneficial in projects with tight spatial constraints. - Enhanced Safety

The uniform connection provided by weld couplers minimizes structural vulnerabilities, reducing the risk of failure under load. - Sustainability

The use of weld couplers contributes to sustainable construction by reducing material usage and facilitating recycling during demolition. - Versatility

Weld couplers can be adapted to various rebar sizes and grades, making them suitable for a wide range of construction projects.

Types of Weld Couplers

- Standard Couplers

Ideal for general-purpose connections, standard couplers provide a simple yet effective solution for joining rebars. - Tapered Threaded Couplers

These couplers use a tapered thread system for a secure connection, offering excellent tensile strength and ease of installation. - Grout-Filled Couplers

Designed for applications where welding is not feasible, these couplers use grout to achieve a strong and durable bond. - Weldable Couplers

Specifically designed for direct welding to structural steel, these couplers are used in complex constructions requiring a steel-to-rebar connection. - Position Couplers

Position couplers are used when the rebars cannot be rotated for threading, providing flexibility and efficiency in installation.

Best Practices for Using Weld Couplers

- Quality Assurance

Ensure that weld couplers meet industry standards and certifications to guarantee optimal performance and safety. - Skilled Installation

Employ trained personnel to install weld couplers, ensuring proper alignment and welding for maximum strength. - Regular Inspections

Conduct periodic inspections to verify the integrity of the connections and address any issues promptly. - Compliance with Standards

Adhere to local building codes and international standards to ensure the reliability of the reinforced structure.

Conclusion

Weld couplers have revolutionized the construction industry by offering a reliable, efficient, and sustainable solution for reinforcing concrete structures. Their ability to connect rebars seamlessly, reduce material wastage, and enhance structural integrity makes them indispensable in modern engineering projects. Whether you’re building a high-rise skyscraper, a sprawling bridge, or a resilient dam, weld couplers ensure your structure stands the test of time.

Investing in high-quality weld couplers not only strengthens your project but also contributes to the efficiency and sustainability of construction practices. As the demand for robust infrastructure grows, weld couplers will continue to be the cornerstone of reinforced concrete construction.

Whether you’re working on a large-scale infrastructure project or a niche engineering venture, SNTP’s weld couplers are the ultimate choice for unmatched performance. Partner with SNTP to experience the difference that quality and innovation can bring to your projects.

Partner with SNTP Today

© Copyright 2017.SNTP All Rights Reserved.

Design & Developed By Star Web Maker