+91 9953 65 9594

Why Every Construction Site Should Consider Using Rebar Couplers

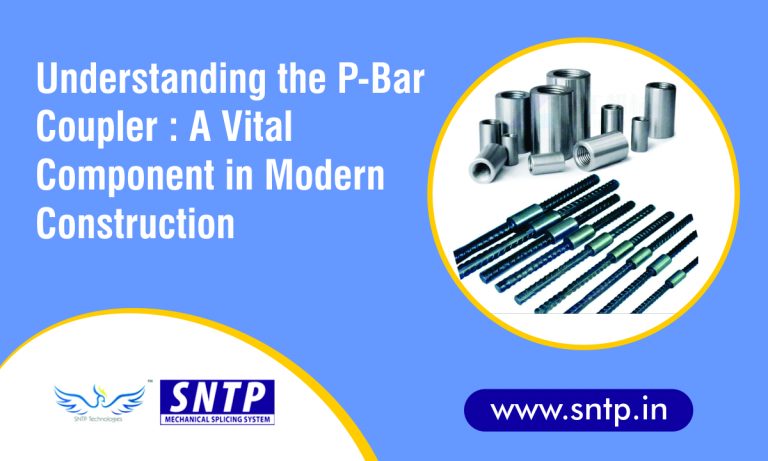

In modern construction, efficiency, durability, and sustainability are critical factors in determining the success of a project. Rebar couplers have emerged as an innovative solution for connecting reinforcement bars, providing numerous advantages over traditional lap splicing methods. Here’s why you should consider using rebar couplers in your construction projects:

1. Improved Structural Integrity

Rebar couplers ensure a direct connection between reinforcing bars, facilitating better load transfer. This eliminates the weak points that can arise from overlapping bars, thus enhancing the overall structural integrity of the construction. They are particularly advantageous in projects requiring high strength, such as bridges, skyscrapers, and industrial facilities.

2. Space Optimization

Traditional lap splicing often results in congestion of reinforcement bars, which can lead to difficulties in concrete pouring and vibration. Rebar couplers reduce this congestion, allowing for more efficient use of space and smoother concrete placement.

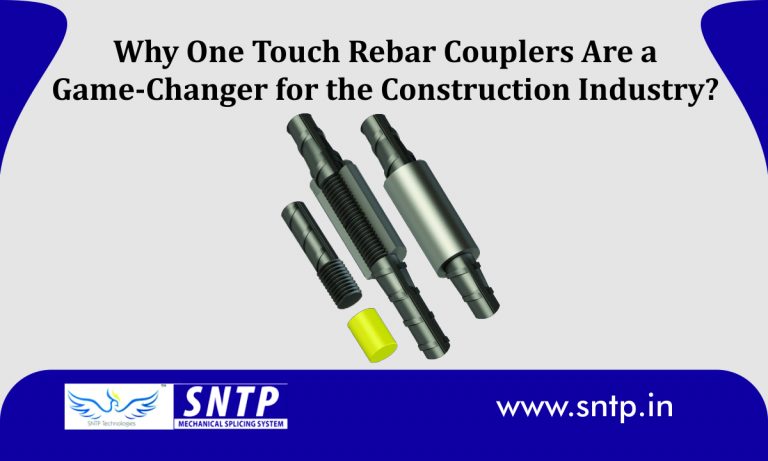

3. Ease of Installation

Installing rebar couplers is straightforward and less time-consuming compared to the lengthy process of overlapping and tying bars. This simplifies on-site operations, reducing labor requirements and potential errors.

4. Material Savings

Lap splicing involves overlapping bars, which increases material usage. Rebar couplers eliminate the need for overlaps, leading to significant material savings. This is particularly beneficial in large-scale projects where even small savings can add up.

5. Sustainability and Waste Reduction

By minimizing material usage, rebar couplers contribute to more sustainable construction practices. They also reduce the generation of scrap steel, aligning with environmental goals and reducing overall project waste.

6. Flexibility in Design

Rebar couplers provide greater design flexibility, especially in complex structures where precise alignment of reinforcement bars is essential. They allow for adjustments and corrections during installation, ensuring adherence to design specifications.

7. Compliance with Building Codes

Many international construction standards and codes, such as ISO and ASTM, recognize the use of rebar couplers. They are approved for use in seismic zones and other critical applications, ensuring that your project meets the required safety and quality standards.

8. Durability and Longevity

Rebar couplers are made from high-grade materials that resist corrosion and wear, ensuring long-term durability. This makes them ideal for projects exposed to harsh environmental conditions or requiring extended service life.

Applications of Rebar Couplers

Rebar couplers are widely used in:

- High-rise buildings

- Infrastructure projects like bridges and tunnels

- Industrial facilities

- Nuclear power plants

- Seismic zone constructions

Partner with SNTP to revolutionize your construction projects and build with confidence.

Why SNTP for Rebar Couplers?

At SNTP, we prioritize innovation, quality, and customer satisfaction. Our rebar couplers are designed to meet the specific needs of modern construction projects, offering unmatched durability and performance. With SNTP, you get:

- High-quality products tested for reliability.

- Expert guidance to choose the right couplers for your project.

- Competitive pricing and timely delivery.

Conclusion

Rebar couplers are a game-changer in the construction industry, offering superior performance, cost savings, and sustainability benefits. Whether you’re working on a small residential project or a large infrastructure development, incorporating rebar couplers can enhance the efficiency and durability of your construction.

By choosing SNTP’s rebar couplers, you not only enhance the strength and efficiency of your structures but also contribute to sustainable and cost-effective building practices.

Take your construction projects to the next level with SNTP’s rebar coupler solutions. Build stronger, smarter, and safer today!

© Copyright 2017.SNTP All Rights Reserved.

Design & Developed By Star Web Maker